Automatic backflush filters are designed to protect engines by keeping fuel and lubricating oil clean. However, Gard’s recent claims experience shows that when these filters fail, they can become a serious source of engine damage, with potentially costly and time-consuming consequences.

Written by

Published 15 December 2025

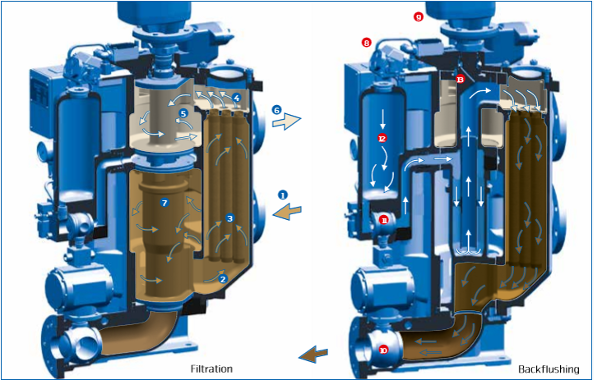

Automatic backflush filters for fuel and lubricating oil cleaning have been in operation for many years and have become common in many engine installations. The filters generally consist of one or more chambers with a set of candles of fine wire mesh that the oil flows through. Larger particles get stuck on the surface while smaller particles flow through the filters and back into circulation.

The difference compared to traditional filtration is the backflush sequence, which is normally pressure triggered, dependent on make and type of your installation. When the differential pressure reaches a set value the filter compartment closes and the oil flow stops. Simultaneously, a new chamber opens to allow continuous filtration and engine operation. Air is then forced through the closed chamber, rinsing the candles before the chamber is then refilled with clean oil and set in standby for further operation (as illustrated by the graphics below).

Source Boll & Kirch Filterbau GmbH

Source Boll & Kirch Filterbau GmbH.

At Gard, we have seen several claims where this fine filter mesh has disintegrated in use, resulting in pieces of the wire mesh entering the lube oil system and severely damaging engine bearings.

Differential pressure concerns

Pressure-triggered rinsing cycles are an inherent risk. If the filter candle mesh start disintegrating, the mesh becomes riddled with holes. With enough ruptures, the differential pressure drops, as the oil will follow the easiest route through the mesh. This will lead to a free flow through the housing, with oil potentially carrying wire mesh parts directly into the engine. From the cases seen there have been no warning of this prior to engine taking damage. Depending on the make and type of your installation if there are no counter on the rinsing cycles performed an abnormally reduced differential pressure is perhaps your only warning.

The damages

The small wires of the mesh break off and can travel through the entire lubrication system, causing severe damage. This damage will be primarily located on bearing surfaces on camshafts and crankshafts. This will in turn create severe surface deterioration and breakdown that can damage the engine even further and lead to dangerous situations . Replacement of main bearings and even the crankshaft itself can be very expensive and time consuming. In one Gard case, replacement of a crankshaft is expected to cost 2.2 million USD with a 8-12 week period just to source the new equipment.

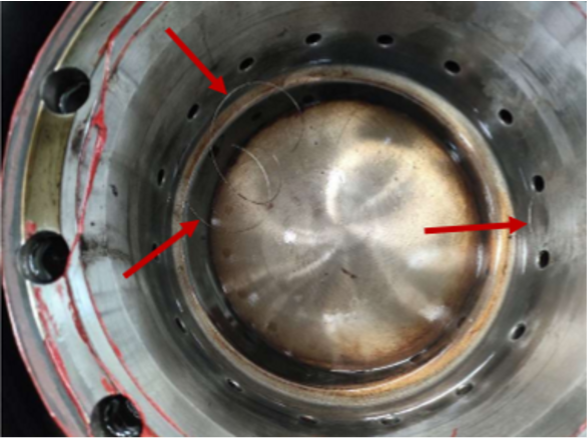

Bearing with severe damages from debris.

Where deterioration of the mesh is found, mechanical and chemical cleaning of the entire system affected will be required prior to operation. If the cleaning process is substandard, new damages may arise swiftly after repairs have taken place.

How to avoid serious incidents

Depending on the make and type of your filters, maintenance requirements will differ. In the matters seen by Gard, disintegration is either due to mechanical damages from rough handling by the crew or old candles having suffered excessive rinsing cycles and use beyond the expected lifetime. The lifetime is determined by shelf-life storage conditions, rinsing cycles and handling.

During the rinsing cycle, the pressurized air from the common air system flows through the candles, forcing away debris and sediments. This exerts outward pressure on the candles mesh wall which during normal operation is subject to inward pressure. The candle can tolerate a finite number of cycles before deterioration occurs. As these systems in general are designed as autonomous systems, cycle tolerance will vary depending on oil type and fouling. Monitoring consistency in rinsing cycles is a key indicator for filter operation. Gentle handling of the candles when manual cleaning is performed is vital to ensure reliable operation. Rough manual handling or high-pressure air cleaning may cause damage. Using proper cleaning tools onboard, such as an ultrasonic cleaner unit or cleaning gun which blows horizontally, is recommended.

Candles should be carefully inspected after cleaning. Damage can often be very small and for the untrained eye might not be considered alarming or noteworthy and may not be reported before the filters are set back to service. Besides proper cleaning, how the spare candles are stored is vital for safe usage. If the candles are stored in a clean environment shielded from physical damage they may last for years and still be ready for safe use. If the candles are roughly treated and stored in places where they are subject to damage, it should be carefully considered whether they remain fit for use.

Considering the numerous candles within a filter assembly, error during installation can also contribute to damage and loss of filter function.

When assembling the filter candles, it is important that the locating plate is correctly mounted and that all filter candles are located within the recesses on the locating plate before mounting the top plate. Special attention should be paid to the candles in the inner circumference.

Gard Recommendations:

To maintain backflush filters and prevent damage due to deterioration:

Ensure the correct manual and procedures for the actual filter system installed are available onboard the vessel and that the crew have been adequately familiarised and trained.

To ensure safe operation of the backflush filters, procedures on manual handling addeherent to makers reccomendations should be in place, together with clear procedures on when filters are to be taken out of use due to damage and risk of failure.

The engine crew should be trained to spot even minor damage to the candles. Training on how to handle the filters with care during cleaning is vital. We recommend having cleaning tools onboard like an ultrasonic cleaner unit or cleaning gun which blows horizontally onboard,

If not already installed, a strainer or in-line filter should be installed after the backflush filter to ensure debris from candle disintegration is captured before it contaminates the oil system.

Use OEM parts. If in doubt, contact your filter manufacturer for advice.

Filter mesh started to disintegrate.

Filter wire damage to main bearing.