Gard once again alerts Members and clients to the significant risks involved in the carriage of nickel ore, particularly loaded from the Philippines. The recent tragic loss of life of crew on a bulk carrier off the Philippines has renewed concerns regarding the safety of nickel ore originating from the region. While the cause of the loss has not yet been confirmed, the ship was carrying nickel ore when she capsized and sank.

Published 29 January 2026

Liquefaction of mineral ores, resulting in cargo shift and loss of stability, has been a major cause of marine casualties for many decades as highlighted in Intercargo’s ‘Bulk Carrier Casualty Report 2015-2024’. In particular, the loading and carriage of nickel ore from the Philippines have remained a long-standing concern.

We continue to encounter instances where cargo is loaded in a dangerously wet state, a problem driven by systemic misdeclaration and unreliable moisture management by shippers. While Intercargo’s report notes that the last major casualty with loss of life from cargo liquefaction occurred in 2019 the recent tragedy off the Philippines serves as a stark reminder that this remains a critical safety threat to crew and bulk vessels carrying Group A cargoes globally.

Overview of nickel ore shipments from Philippines

Our correspondent, Pandiman, has prepared a useful report on the shipment of nickel ore from the Philippines. The key points they highlight are as follows:

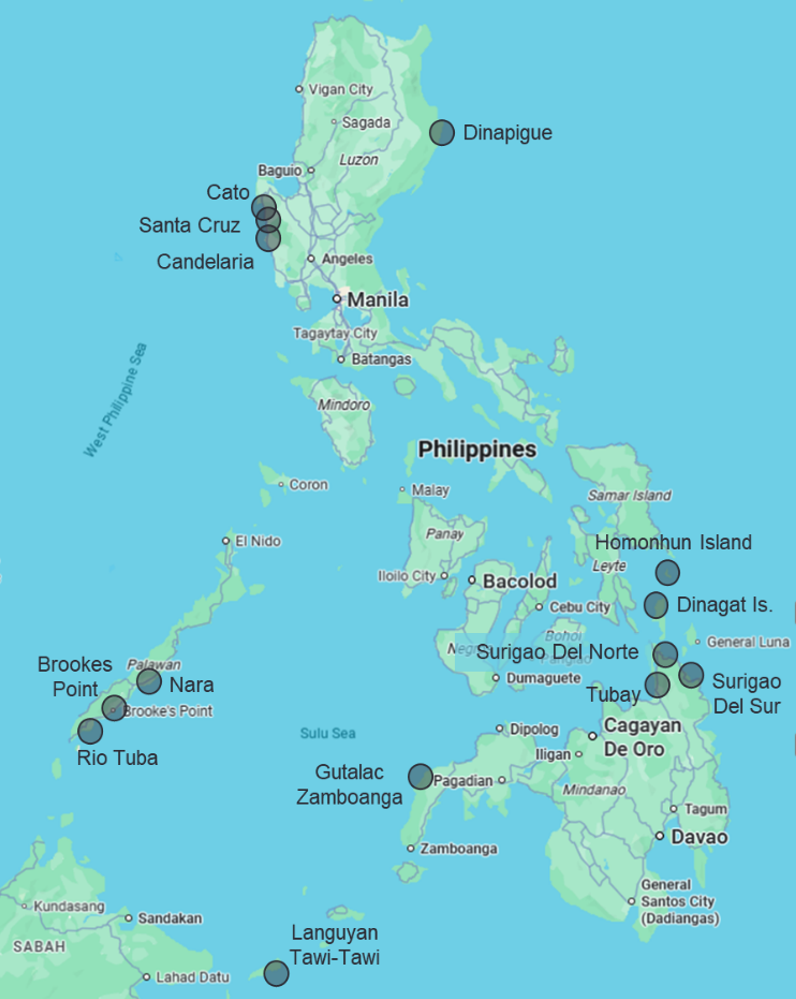

Mining areas: There are 14 nickel ore mining areas across the Philippines, as shown in the image. The bulk carrier that sank recently, had loaded Nickel Ore in Gutalac Zamboanga. Surigao and the surrounding islands remain the most active loading regions. It is worth highlighting that several laden vessels have previously run aground in Dinagat Sound.

Nickel ore mining areas across the Philippines.

Unreliable certification: There are documented concerns as to the veracity of the loading certificates being provided by the local mines in-house laboratories. This has been based on comparison analysis of cargo undertaken at independent laboratories by shipowners. The analysis undertaken for the determination of the moisture content and Flow Moisture Point (FMP) by mining company’s own labs may not follow the IMSBC Code requirements.

Infrastructure shortcomings: Mines commonly stockpile nickel ore in open, exposed areas on or near the foreshore. There are no dedicated jetties or port facilities at these locations. Loading is conducted offshore at anchor using barges, which may be uncovered. The ore is unprocessed, sourced from open‑cast operations, and remains exposed to the elements throughout handling.

Weather challenges: Climate patterns have changed significantly over the past 30 years, with the once clear distinction between the dry and wet seasons now blurred. Frequent rainfall results in inherently wet cargo due to prolonged exposure of stockpiles to the elements.

Obstruction of Verification: Shippers and mines often restrict access to their sites and laboratories, limiting opportunities for independent verification. Local mines frequently decline joint surveys by independent experts representing shipowners. In some cases, vessels have withdrawn and sailed without loading due to the inability to scientifically confirm the cargo’s safety for carriage under the IMSBC Code.

Case study: Liquefaction of cargo loaded in Surigao

Last year, Gard handled a case involving a charterer client positioned mid‑chain in the charterparty, where nickel ore liquefied in the vessel’s holds three days after departing Surigao en route to China. The vessel was fortunately able to reach a port of refuge in Philippines. The shipper’s documentation (the Shipper’s Declaration, TML, MC, and FMP certificates) was found to be inaccurate. All certificates (TML, FMP and MC) had been prepared, approved, and reviewed solely by the mining company. The figures declared were TML 36.19%, FMP 40.21%, and MC 35.31%. Photographs of the incident, along with a video from inside the cargo holds, are provided below.

Nickel ore being loaded from barge

Can tests done by crew

View of liquefied cargo in one of the holds

Vessel listing to port

Another observation in this case was the inclusion of an onerous clause in the sub-charterparty with the voyage charterers who lifted the cargo, which stated: “The Cargo to be tested through the can test only. Once loaded, deemed accepted as safe cargoes by Owners and should not be further sampled/tested. If the cargo condition cannot meet Master’s satisfaction and is not suitable as per can test, the Master/Owner shall be entitled to reject the cargo presented.”

Commercially trying to prohibit sampling and further testing directly contradicts the Master’s obligation and statutory right to ensure the safety of the ship and crew. The clause attempts to shift statutory responsibilities belonging to the shipper and competent authorities onto the vessel and its crew. Specifically, the clause seeks to:

Remove the responsibilities of the shipper and competent authority

Contradict mandatory provisions of the IMSBC Code

Reduce all compliance and safety to assessment of can tests conducted by the crew.

Owners and charterers should carefully review their charterparty terms to ensure that similar clauses that attempt to shift statutory obligations from shippers and competent authorities to the owners or crew are not incorporated. Such clauses are neither safe nor consistent with the IMSBC Code. It is recommended that charterparties incorporate BIMCO’s ‘Solid Bulk Cargoes that Can Liquefy Clause for Charter Parties 2012’.

Mandatory notifications

Members are reminded that they must notify the Club, pursuant to the Club’s mandatory notification requirement for such cargoes, if they plan to fix or charter a ship to load nickel ore from the Philippines (Refer Member Circular 05-12). The same requirements apply to Nickel Ore from Indonesia as well.

Gard’s geofencing

Gard’s geofencing alerts are limited to owned vessels entered with Gard, and do not detect vessels for charterer Members. It is therefore important for charterers to notify Gard every time they fix their vessels for loading such cargo. The main purpose of the geofencing alert is not to monitor our Member’s activity, but to provide support by highlighting the risks involved when carrying cargoes that can liquefy and the precautions that can be taken to mitigate those risks. For further information, please refer to the Gard article ‘Geofencing – targeted and timely loss prevention advice to Members’

Key take-aways

Liquefaction incidents often arise from discrepancies in cargo declarations and lack of independent or certified laboratory testing. In many instances, the documentation presented to the vessel may not fully reflect the actual moisture condition of the cargo, or the shipper's moisture management procedures may not meet the necessary standards. This risk is often heightened when there is lack of oversight by the competent authority.

A key indicator of risk is the shipper's inability to provide an IMSBC Section 4.3.3 document issued by the competent authority (CA) confirming that their procedures have been approved. The absence of this document should be considered a significant warning sign, and Members are advised to proceed with caution.

Owners and crew are also reminded that can-tests are a very basic check and are not foolproof. They are not a substitute for independent laboratory tests. As the IMSBC Code states, even if cargo sample remains dry following the test the moisture content may still exceed the TML. Moreover, even if Group A cargo is deemed safe to carry, it remains important to monitor it throughout the voyage. In line with the IMSBC Code, the cargo surface should be inspected at regular intervals. If signs of liquefaction are observed, the vessel should consider diverting to a place of refuge.