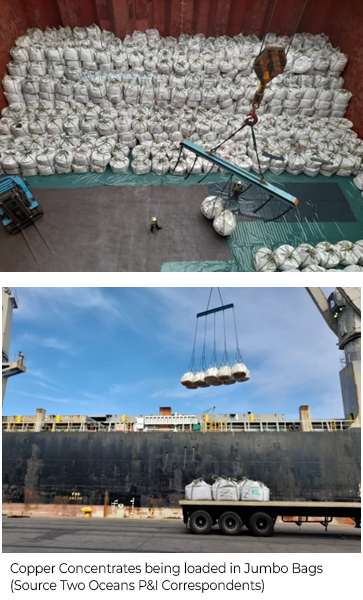

The increased use of jumbo bags (FIBCs) in bulk mineral transport, including those prone to liquefaction, requires heightened awareness of the risks involved. While convenient, the bags’ application to certain cargoes presents distinct challenges.

Bulk cargo in jumbo bags – understanding the risks

Published 23 July 2025

Jumbo bags

Jumbo bags, also known as Flexible Intermediate Bulk Containers (FIBCs), are industrial containers designed for bulk materials. They typically hold 500 kg to 3,000 kg, come in various sizes and shapes, and are constructed from woven polypropylene with an inner polyethylene layer. FIBCs must comply with standards like ISO 21898, specifying details such as their maximum compressive load and safe stacking height to prevent overloading. Higher stacks experience greater acceleration forces during transport. If hazardous goods are involved, it should be checked if they are certified for such goods.

Risks

Deformation and movement of bags during the voyage

During ships' motions in heavy weather, the cargo may move within the bags and the bags may change shape. This results from:

bags not being filled uniformly, and/or

the material properties are not uniformly distributed.

As the material consolidates (reduces in volume) in the bags, it does so at different rates in different locations. In a typical unconfined stow this will lead to local adjustment of the shape and bulk density of the stow. In a jumbo bag, this means that the uniform shape of the bags and the level surface required for neat and stable stacking are compromised, leading to uneven load distribution and reduced stability. The reduced stability subsequently relies upon the tensile strength of the bags to act as a confining action to prevent the flow of the material. The rupture of a bag means its inherent stabilising actions are reduced and potentially contribute to an increase in destabilising forces in the entire stowage. For Group A cargoes, the potential of the bags deforming and compressing under external forces is higher if the cargo is loaded above its FMP even if they were stowed tightly and compact on loading.

Shifting of bags is another associated risk. If stored tightly together and on top of each other in a boxed cargo hold, this normally does not represent a problem, however without a shoring between the bags, the cargo may shift. During the heavy rolling motions of a ship, the bags will seek to fill the voids between them, and during sideways pressure the cargo can be compressed and can also rise within the bags, creating even more slackness in the transverse direction. The shifting of such cargo on several decks can result in the vessel taking a severe list.

Bag integrity

Jumbo bags must be sturdy and well-constructed to withstand the rigours of handling during loading, unloading, and transport. If the bags are damaged, torn, or compromised, it can lead to spillage, contamination, and a loss of product integrity.

Loading heavier items on top of jumbo bags can cause damage due to shifting during transport, often evident at discharge. Excessive top weight has also been a direct cause of bag failure.

Cargo characteristics

Many cargoes transported in jumbo bags present inherent chemical hazards. Owners and crew must be aware of the potential for these cargoes to release toxic and flammable gases. The gases released may not be detectable on commonly used personal gas monitors which generally detect oxygen, flammable gas (usually methane), carbon monoxide, and hydrogen sulphide. Therefore, safety measures need to be taken when the crew enter the holds with such bagged cargo. For example, Ferrosilicon UN1408 (Group B, Class 4.3 with subsidiary hazard 6.1) can release highly toxic gases, like arsine and phosphine. While ferrosilicon can be carried in packages under the IMDG Code, it is only when carried in bulk under the IMSBC Code that it is necessary to have detectors for hydrogen, phosphine, and arsine onboard, with measurements taken at least every 8 hours.

Additionally, certain Group A cargoes, like copper concentrates, possess self-heating properties. When these cargoes are bagged, heat can become trapped, significantly increasing the risk of fire within the bag.

Stow height

When loading Group A cargoes or materials prone to caking into jumbo bags (FIBCs), determining the maximum safe stow height is paramount. This height primarily depends on the maximum permitted stacking load of the specific FIBC, usually shown on the bag itself . There is no fixed regulated limit for stack height as long as the stacking load on the bottom bags is not exceeded, and the stowage is secure, tight, and all void spaces are properly chocked. Often, FIBCs are stowed right up to the hatch coaming. However, a cargo's tendency to compact must also be considered. For example, automotive-grade urea compacts more readily than agricultural-grade urea, so a lower stow height for the automotive grade could prevent it from compacting too much.

Fire hazards

Although cargo is not typically seen as an initial source of fires, incidents have been observed at loading and discharge ports caused by discarded cigarettes from stevedores, igniting the plywood and packaging of jumbo bags. Alarmingly, these fires sometimes led to the release of toxic gases from the affected cargo, making firefighting much more complex.

Incompatible chemicals

Loading multiple different chemicals into the same hold requires careful consideration, as ship’s crew cannot be expected to know all chemical compatibilities. Ideally, different chemicals should not be loaded together in the same hold to prevent incidents due to chemical incompatibility or contamination claims. If mixed chemicals must be loaded together, it is crucial to obtain Safety Data Sheets (SDS) for all chemical cargoes from the shipper. An expert should carefully check manifests to confirm no incompatible chemicals are loaded in the same hold and to identify potential misdeclared cargoes. Failing to do so, especially with torn jumbo bags, can lead to the admixture of incompatible chemicals, resulting in fires and further reactions within the hold, incurring significant costs from lost goods, clean-up, and delays.

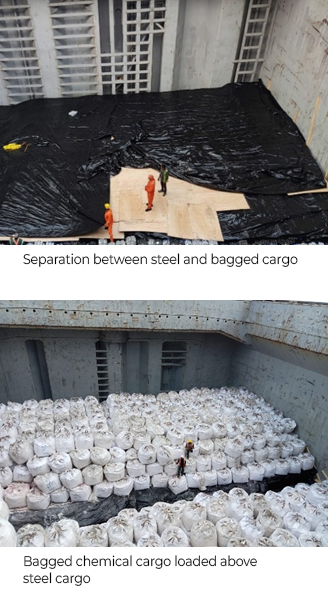

Beyond chemical reactions, bagged chemical cargoes can also pose a physical threat to other goods in the hold. For instance, if chemical-filled jumbo bags are stowed above other cargo and the bags’ integrity is compromised, the contents can severely damage the underlying goods. Gard recently managed a high-severity claim involving significant corrosion to steel cargo. This damage stemmed from the spillage of a chemical cargo stowed directly above the steel. As per the incident report, the damage stemmed from several factors, including cargo incompatibility, inadequate separation, and damaged or torn bags.

IMSBC or IMDG Code?

Jumbo bags are not considered as bulk cargo, and bags may be used by shippers to avoid IMSBC Code requirements for cargoes that may liquefy (Group A), or which pose chemical hazards (Group B). In these instances, as the cargo has been loaded in bags, it is the IMDG Code that applies, rather than the IMSBC. We have seen an increase in the number of instances in which Group A cargoes are being loaded into jumbo bags; some of these cargoes fall under UN 3077 (Environmentally Hazardous Substances, Solid, N.O.S., Not otherwise specified). Where the cargo has a UN number under the Code, a supporting dangerous goods declaration must also be provided by the shipper.

IMO's advice on FIBCs

SOLAS Chapter VI, Carriage of Cargoes, Part A Reg.5.1 deals with stowage and securing of cargoes and requires: "Cargo, cargo units and cargo transport units carried on and under deck shall be so loaded, stowed and secured as to prevent as far as practicable, throughout the voyage, damage or hazard to the ship and the persons on board, and loss of cargo overboard". Regulation 5.6 further requires an approved "Cargo Securing Manual", for all types of ships engaged in the carriage of all cargoes other than solid and liquid bulk cargoes. IMO has also issued Guidelines on the preparation of the cargo securing manual (MSC/Circ.745).

The Code of Safe Practice for Cargo Stowage and Securing has some advice on particular types of cargoes, and Annex 10 deals with Flexible Intermediate Bulk Containers. It states that "The ideal ship for the carriage of FIBCs is one with wide hatches so that the FIBCs can be landed directly in the stowage positions without the need for shifting" and that "The cargo spaces should, where practicable, be rectangular in shape and free of obstructions". The Code of Safe Practice for Cargo Stowage and Securing seems to acknowledge the problems of vessels with tween-decks, advising that "when FIBCs have to be stowed in deep hatch wings, easy access and sufficient manoeuvring space for suitably adapted fork-lift trucks should be available".

The Code also advises that when FIBCs are stowed athwart ships, one should start the stowage from both sides of the cargo hold, so any void space will be at the centre and not in the wings. That void space should then be chocked off. Where a tween-deck or lower hold is only partly filled with FIBCs, the bags must be shored off and wire lashings should be used from side to side of the cargo hold to secure the bags. The Code does well in asking for wire lashings, too often it has been seen that synthetic ropes may stretch or are of insufficient strength to secure heavy cargo in heavy weather.

Key recommendations

Pre-loading preparations

Request cargo details and dangerous goods declaration: Start by asking shippers for detailed information about the cargo, specifically its shipping name (not just common trade names), to understand the risks. If it is a hazardous cargo under the IMDG Code, a dangerous goods declaration is essential.

Obtain Safety Data Sheets (SDS) for bagged chemicals: For bagged chemicals, the shipper must provide the SDS. These documents are crucial for identifying any associated hazards, especially when multiple bagged chemicals are loaded into the same hold, to check for chemical incompatibilities.

Cross-reference with IMSBC Code for bulk-hazardous cargoes: When shipping cargoes typically hazardous in bulk but are now in packages, it is suggested to consult the IMSBC Code for precautions and to be aware of any bulk-related hazards.

Request evidence of packaging assessment: Ask shippers for evidence that they have assessed the cargo's properties against the packaging's strength and fill capacity. This ensures the packaging has sufficient tensile strength for the material's weight, plus a safety factor.

Loading and stowage

Follow cargo securing manuals and codes: Owners and the masters must ensure cargo is loaded in strict accordance with the vessel's Cargo Securing Manual (CSM), the Code of Safe Practice for Cargo Stowage and Securing (CSS Code), and the IMDG Code.

Consider compartmentalization for stability: Compartmentalizing the stow into units is recommended. This can reduce forces that lead to destabilization while increasing the restraining forces, improving overall stability.

Supervise stevedores and enforce safety protocols: To maintain safety, crew members should closely supervise stevedores. This includes enforcing no-smoking policies and ensuring proper enclosed space entry protocols are followed, especially if the cargo might emit hazardous gases.

We would like to thank Karwei So of Brookes Bell for her contribution to this article.