Cashew Nut Shell Liquid is being considered as an alternative source of biofuel. These compounds are already being detected in conventional marine fuels like ULSFO, VLSFO, and HSFO and Gard has handled claims where the presence of these compounds in conventional fuels has resulted in operational problems or machinery damage for vessels.

Cashew Nut Shell Liquid blends - a marker for a problematic fuel?

Published 20 May 2025

Growing demand for low to zero carbon fuels across transport sectors to meet environmental regulations has increased interest in alternative sources. Fatty Acid Methyl Esters (FAME) are popular for biofuels, but high demand across various transport sectors exceeds supply. Cashew Nut Shell Liquid (CNSL), a byproduct of the cashew industry, is considered an alternative source of biofuels.

What is CNSL?

Cashew Nut Shell Liquid, a cost-effective renewable fuel, differs from FAME biofuels. As a substituted phenol, its high reactivity and lower stability are attributed to its elevated iodine value. Beyond its fuel potential, CNSL is already used in the production of plastics, resins, adhesives, laminates, and surface coatings. Its high acid value (> 3mgKOH/g) also makes it significantly corrosive. CNSL’s key phenolic compounds that tend to polymerize, forming gums and fuel deposits include:

Anacardic Acid is a major contributor to CNSL's high acidity. Thermal decarboxylation converts this to cardanol, reducing acidity and enhancing stability.

Cardanol, also known as Ginkgol, is a stable phenolic compound derived from anacardic acid with improved combustion and lubricity properties.

Cardol, also referred to as Olivetol, is a dihydroxybenzene derivative with surfactant-like behaviour.

Cases of CNSL causing operational problems

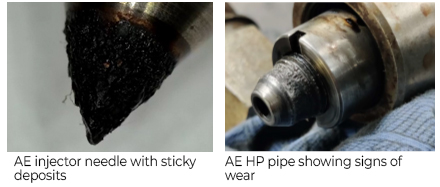

Cashew Nut Shell Liquid, despite its benefits of increased lubricity and energy content, poses challenges due to high acidity, poor combustion, and corrosiveness. Widespread contamination of conventional fuels with CNSL was reported in the ARA region in 2022, leading to operational problems such as fuel sludging, fuel injector failure, engine part corrosion, filter clogging, fuel system deposits, turbocharger nozzle ring corrosion, fuel pump plunger and barrel wear, and damage to Selective Catalytic Reactor (SCR) units. Since these incidents, Gard has handled several cases involving the detection of phenolic compounds originating from CNSL in varying concentrations.

Case study 1

A vessel bunkered HSFO in Southeast Asia. Despite passing initial ISO 8217, Table 2 testing and preliminary GCMS screening, the fuel soon caused main engine exhaust temperature alarms, followed by leaking injectors and stuck fuel valves. The vessel required an 800nm tow to safety. Subsequent GCMS revealed over 10,000 ppm of Cardonol. Costs incurred exceeded USD 800,000.

Case study 2

A vessel experienced significant operational issues shortly after using ULSFO that initially passed ISO 8217, Table 2 testing. Fuel was stemmed at a port in Northern Europe. Problems included high main engine exhaust temperatures, auxiliary engine failure and fuel leaks, fouled nozzles, and damaged high-pressure fuel pipes, necessitating replacement of all fuel pumps and valves. GCMS analysis revealed high levels of Cardanol (> 30,000 ppm), Cardol (> 5,000 ppm), and Anacardic Acid (> 1,000 ppm) totalling 1.24% by mass of the fuel composition. The cost of repairs exceeded USD 400,000.

We are aware of several vessels having been impacted by the same bunker delivery.

It is worth noting that there have been instances where CNSL-blended conventional fuels have been stored and combusted without any operational issues being reported.

Testing of CNSL as biofuel – VPS’s experience

VPS, in their recently published article ‘Cashew Nut Shell Liquid – Biofuel Saviour or Concerning Contaminant?’ shared the results of their testing of CNSL products, blended with marine gas oil (MGO), very low sulphur fuel oils (VLSFO) and high sulphur fuel oils (HSFO). Fuel Combustion Analysis (FCA) revealed a spectrum of outcomes for estimated cetane number, ignition delay, and rate of heat release (ROHR), with CNSL blends showing a performance gradient: the HSFO blend performed particularly poorly, the VLSFO blend showed improvement, and the MGO blend yielded the most favourable results.

Whether the blends were 80/20, 70/30 or 50/50 Fossil/CNSL, the blends using HSFO consistently gave the poorest FCA results. This may be due to a negative interaction between the asphaltenic content of the HSFO and the acidic nature of the CNSL. Each of the CNSL blends gave poorer FCA results when compared with the 100% fossil fuels, HSFO, VLSFO, MGO and 100% FAME.

They have also shared a B100 case study, where the fuel was assumed to be 100% FAME, but the analysis revealed that it was 40% FAME, 10% FAME Bottoms and 50% CNSL. Technically, the fuel was still B100, but with the Biomass comprising of different components. This emphasizes the importance of due diligence regarding fuel procurement for charterers and owners.

CNSL and ISO 8217

One of the experts Gard consulted reported that “CNSL is not a permissible component in bunker fuels, on the basis that same is not a hydrocarbon derived from petroleum refining, nor is it derived from an alternative permissible hydrocarbon source and thus falls foul of Clause 5 of ISO 8217.” VPS comments along the same lines in their alert “For the purposes of ISO 8217:2024 and all preceding versions, CNSL is not recognized as a standard fuel component. Accordingly, its presence in a marine fuel may be considered a contaminant and potentially classified as off-specification when assessed against the ISO 8217 standard”.

It's important to note that Annex B of ISO 8217:2024 acknowledges that various chemical species or materials (though not exhaustively listed) can cause operational issues. Consequently, fuel oil purchasers might need to conduct advanced testing to identify substances that could render the fuel unsuitable for the engines. Moreover, although ISO 8217:2024 addresses biofuels, its scope does not extend to all forms of biomass.

Key recommendations

For conventional fuels:

Owners and charterers should request confirmation from the fuel supplier regarding the presence and quantity of any CNSL compounds blended into the fuel prior to procurement, and this should be stated on the Certificate of Quality.

Fuel purchasers might need to opt for advanced fuel testing methods to identify CNSL compounds. This detectability is a key consideration before using the fuel.

If CNSL compounds are detected, the decision to consume the fuel or debunker may necessitate external consultation, depending on the concentration of these CNSL compounds and the presence of other contaminants.

For biofuels:

Given that CNSL-based biofuels are not specifically covered by the ISO 8217 standard, their use requires supplementary testing. Owners are advised to consult their testing laboratories to determine the necessary tests.

Based on the biofuel case study shared by VPS, it is recommended to verify with the supplier the specific biomass source and production method used in the biofuel.

Request evidence of the biofuel blend shop trial results from the fuel supplier.

It is advisable to seek guidance from engine manufacturers regarding the use of such fuel.

Detailed instructions, particularly regarding the special parameters for onboard biofuel storage, handling, treatment, and use, must be sent to the vessel.

We would like to thank Capt.Rahul Choudhuri of VPS for assistance with this article.