Detailed explanation of dynamic separation in Group A bauxite cargoes.

Dynamic separation in Group A bauxite cargoes

Published 15 October 2017

Further to our update of 3 October 2017, we provide below a more detailed explanation of “dynamic separation”, based on the IMO’s Global Bauxite Working Group (GBWG) report. Like liquefaction, the process of dynamic separation can be prevented by ensuring that the bauxite has limited fines content and a limited moisture content, as both particle size distribution and moisture content are the main parameters for the occurrence of this phenomenon.

It is important that mariners understand what is happening with the cargo in the hold as changes in appearance provide a possible early warning sign of changes that can eventually lead to vessel instability. The draft new schedule for Group A bauxite states:

If free water or a liquid slurry above the cargo or fluid state of the cargo is observed, including the flattening of the cargo, during voyage, the master shall take appropriate actions to prevent cargo shifting, loss of stability due to free surface effect and potential capsize of the ship

An atypical motion of the ship (wobbling) may also be indicative of cargo instability and the master shall consider appropriate action.

The Australian Maritime Safety Authority has helpfully produced a video describing dynamic separation and is available here.

https://www.amsa.gov.au/vessels-operators/cargoes-and-dangerous-goods/dynamic-separation-cargoes

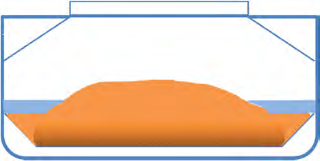

Figure 1. The cargo upon loading in the form a pile, essentially uniform, homogenous and unsaturated.

Figure 2. Cargo compaction due to ship’s motions results in moisture migrating towards the bottom of the cargo pile. Once the moisture content at any location in the pile reaches a critical level, the dynamic forces on the cargo cause moisture to flow to the nearest low pressure pile surface in the corner/bulkhead/wall boundary. As this flow of water continues cargo moisture separates from the solid cargo and forms free surface pools at the corners of the hold. The solid cargo at the bottom of the pile and cargo pile in the centre of the hold becomes drier than the as loaded cargo in figure 1. Cracks may be seen developing in the pile surface.

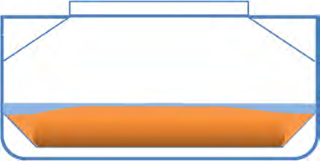

Figure 3. The upward and outward movement of moisture causes the upper part of the cargo to slump/flatten. A deeper perched water layer forms in the pile corners. These free water surfaces slosh during ship’s motions causing erosion of the cargo pile edges. Cargo particles become trapped in the water forming a slurry.

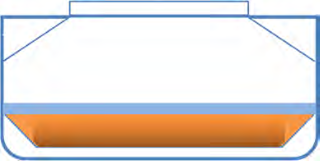

Figure 4. As moisture separation, cargo slumping and erosion of the cargo pile continues the free slurry surface that is perched above the solid cargo extends to the full width of the cargo hold. The upward movement to moisture entrains ultrafine particles with it at the surface and prevents the moisture from being readily adsorbed back into the cargo bulk.

Figure 5. The final state of the cargo after dynamic separation is complete. The cargo pile is now completely flat with a free surface slurry layer that extends the full width of the cargo hold which is perched above the solid cargo. If left unchecked this movement of free surface slurry over the top of the cargo has the potential to further reduce stability and increase the risk of capsize.