Gard has seen five fires originating in the main and auxiliary engines in the first month of 2025 alone. Tragically, some of these fires resulted in fatalities and serious injuries to seafarers. While it is too early to draw any conclusions about the rest of the year, it may be helpful to review our experiences from recent years. Although the main cause of these fires may not be identical, there are certain similarities in the underlying patterns of the fires.

Written by

Siddharth Mahajan

Team Leader, Loss Prevention Asia

Kim Watle

Senior Business Analyst

Svend Leo Larsen

Senior Claims Adviser

Published 13 February 2025

Introduction

Every year fires on board ships lead to loss of lives and severe damage to the ships themselves. Most fires on board ships originate in the engine room where the three ingredients for a fire, namely fuel, oxygen and a source of ignition, exist in abundance. These do not only start the fire but also feed and intensify it further. Fire safety is not only about detecting and fighting a fire, but also about preventing it from igniting in the first place.

In this article we will focus on how these fires can be prevented. We will touch upon some of the main causes of engine room fires and explore insights from our claims data to understand the frequency of such fires before setting out some recommendations on how to mitigate the risks of these fires occurring.

How do most engine room fires start?

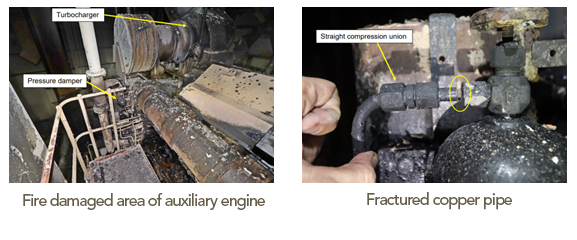

A review of Gard’s hull and machinery (H&M) claims for the years 2017-2024 related to fires and explosions on vessels, shows that nearly 60% of all such fires originated in the engine room. Nearly two thirds of these engine room fires occurred on the main and auxiliary engines or their associated components such as turbochargers. The majority of these incidents were caused by a failure in a flammable oil system, most often in the low-pressure fuel oil piping, allowing spray of oil onto an unprotected hot surface. Below is an example from our claims portfolio.

Case study

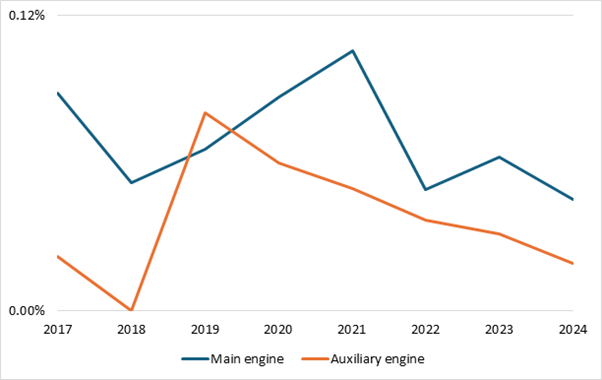

A copper pipe that was part of the fuel oil pressure gauge supply pipework for one of the auxiliary engines fractured. Due to a missing metal spray shield the fuel sprayed onto the unprotected hot surfaces of the nearby turbocharger and the exhaust system which had temperatures of more than 400 °C. The fuel ignited causing extensive damage to auxiliary engines and power distribution cables. The vessel was out of service for 40 days to carry out repair works.

Investigation by experts showed that the copper pipe that fractured did not match the original design and had a lower wall thickness. There was no record of any previous repairs carried out to the fuel system pipework. The pipe assembly on the other three auxiliary engines appeared to be of original installation comprising of a steel pipe. The spray shield was removed during maintenance and not re-installed. Insulation was also suspected to be inadequate since exposed sections around the exhaust manifold and turbocharger were noticed on other three auxiliary engines. The investigators concluded that the heat shielding arrangements on the fire damaged auxiliary engine did not meet the relevant SOLAS regulations, II-2/2.2.6.1.

In the above case, there are two main aspects which need to be highlighted.

First is the leakage of flammable oil; and

Second is the inadequate protection to prevent highly flammable fuel from coming in contact with a source of ignition.

Leakage or spray of fuel due to a failure in the oil system

Below we list some of the most commonly occurring causes of fuel spraying from low pressure piping systems. The list is by no means exhaustive, but a review of past Gard cases has shown that below listed failures occur frequently.

Piping, piping connections and other associated components, such as o-rings, were not original parts or of a type recommended by the manufacturer. In some cases, modifications had been done by the crew under existing management, whilst in others the crew were not aware of such modifications as they had been done under previous ownership or management.

Piping connection had not been tightened to the required torque and with time it loosened due to, for example, vibrations. Another reason may be incorrect assembly after maintenance.

Bolts for flanges or filters breaking due to fatigue caused by overtightening over a period of time. In some cases, securing bolts were also found loose or missing altogether.

Fatigue fracture of pipes. Such pipes are typically not well supported along their entire length, which causes excessive stress due to vibrations. Lack of support may be attributed to the design or failure to reinstall the holding brackets after maintenance.

Fuel oil filter covers coming loose and displacement of the spindle from the top cover for various reasons.

Rupture of rubberized hoses due to degradation caused by the heat generated from nearby machinery, or use of non-original spare part.

Engine manufacturers' design improvement recommendations not implemented

Oil coming in contact with hot surfaces

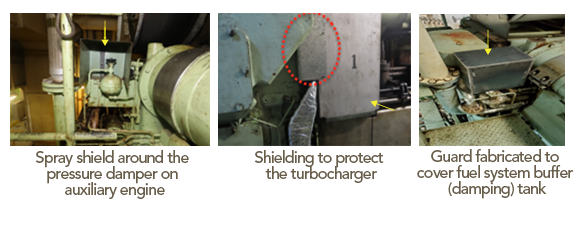

Shielding can either be by insulating hot spots with thermal insulation or anti-splashing tapes, and/or by using physical barriers such as spray shields.

The potential risks associated with the proximity of fuel oil/lubricating oil piping installations to hot surfaces may not be comprehensively addressed during the newbuild stage by the shipyard or the vessel's classification society.

Some typical issues with insulation which we have seen in our claims portfolio are:

the quality may differ from yard to yard, it can deteriorate with age,

it may not have been fixed back properly after maintenance, and

it can become soaked with oil over a period of time due to minor leakages.

As for physical barriers:

they may not have been part of the original design and therefore not fitted, or

where fitted, they may not have been installed back in place after maintenance has been carried out on the oil system, as in our case study, and as time passes may even be misplaced.

Older vessels need more attention

One of the factors which must be considered when assessing fire risks in engine rooms is the age of vessels. The risk of leakages from machinery may increase as ships grow older. We discuss this further below but highlight here some of the main issues that can increase the risk of fire in the engine room on older vessels.

Protection of hot surfaces may degrade, thereby increasing the probability of ignition and risk of fires.

Older vessels can face cuts to their maintenance and safety budgets as they near the end of their service life.

A vessel may have changed ownership and management a number of times during its life, and this can have a direct impact on the consistency of maintenance in the engine room.

Older vessels may lack the advanced fire detection and suppression systems found on newer ships.

Sourcing spare parts for older machinery can be difficult and expensive, potentially leading to delays in repairs and the use of less reliable temporary fixes

Typical hotspots in the engine room

Based on previous fire incidents handled by Gard, we have found that the below listed areas acted as a source of ignition in most cases. The temperature of these areas can easily exceed 500 °C which may be well above the oil’s auto ignition temperature.

Exhaust manifold, pipes and associated flanges

Exposed areas of boilers

Turbochargers

Indicator valves on cylinders

Heater for purifier units

Electrical wires/components and switchboards. Melting or smoldering of cables can also contribute to the transmission of heat

Data insights – do the numbers tell their own story?

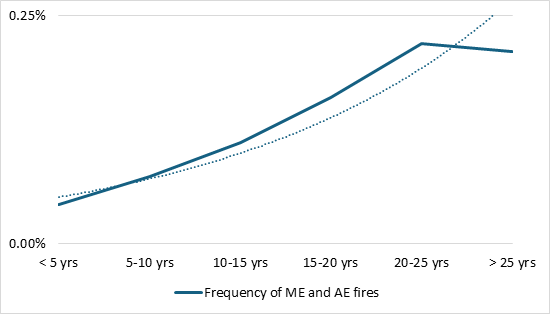

In Gard, when analyzing trends, we, just like Cefor (The Nordic Association of Marine Insurers), follow closely the frequency trends of incidents over a given time period. This way we are also able to account for the growth in our portfolio from one year to the next. From 2017 to 2024, main engine fire frequency has shown a slight downward trend, while auxiliary engine fires have remained steady.

Frequency of engine fires (GARD H&M data)

Between 2017 and 2024, main engine fires occurred on an average of 0.07% of vessels annually. This translates to approximately 7 fires per 10,000 vessels each year. While this percentage may seem low, the consequences of such fires are severe, impacting human life, the environment, and causing substantial financial losses. Auxiliary engine fires were slightly less frequent at 0.04%.

Vessel Segment: Do specific vessel types present a greater risk of machinery fires?

Passenger ships experience the highest combined frequency of main and auxiliary engine fires, and among cargo vessels, car carriers and container vessels experience a higher frequency of such fires, possibly due to a higher number of auxiliary engines on all these ships compared to other vessel types. Bulk carriers, on the other hand, generally demonstrate better performance in this area. When examining the various size segments within cargo ships, the mid-size vehicle carrier segment (10k – 20k dwt) and Container Intermediate 2 segment (6,000-8,000 teu) had the highest main engine fire frequency. Whereas, for auxiliary engine fires, it is the container feeder segment (<3,000 teu).

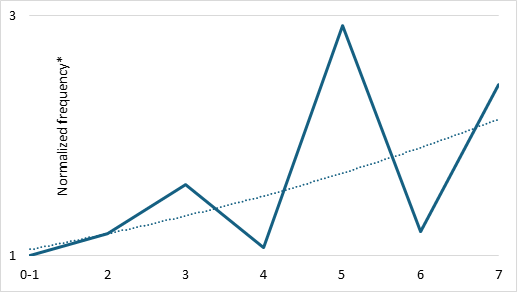

Age as a factor

As previously discussed, vessel age is a significant factor in fire risk assessment. Our data reveals a higher incidence of engine room fires in older vessels, as shown in the graph below.

Frequency of engine fires by age of vessels (GARD H&M data)

Interestingly, concentrated inspection campaigns (CIC) by Port State Control MoUs on ‘Fire Safety’ carried out in 2023 concluded that the rate of detention for vessels failing certain CIC items seemed to increase as ships get older. See the Paris MoU report and Tokyo MoU report.

Poor port state inspection performance linked to increased fire risk

Ships accumulating more deficiencies per inspection over the three years preceding an incident face a heightened risk of fire in their main or auxiliary engine. This risk increases with the number of deficiencies. Numerous deficiencies might be indicative of a broader problem with maintenance on board and safety culture within the organization. It's important to note that beyond seven deficiencies per inspection, the available data becomes too limited.

Number of deficiencies per PSC inspection

*Note: Normalized frequency shows the relative risk of an engine fire for vessels with different numbers of deficiencies per inspection, using vessels with ‘0-1 deficiencies per inspection’ as the baseline. For example, vessels with 5 deficiencies per inspection have nearly 3 times the risk.

Recommendations

Failure in an oil system followed by deposit of oil onto a high temperature surface is the leading cause of engine room fires. We have the following three key recommendations which can help owners, managers and their crew reduce the risk of such fires occurring.

1. Identifying sources of leakages

Checking fuel and lube oil pipes for loose fittings, missing bolts on flanges, non-metallic hoses in areas where the temperatures can exceed the oil’s ignition point etc., from where oil can spray onto hot surfaces should be part of the vessel’s planned maintenance system. It is recommended that the assessment to identify potential sources of leakages be done on a regular basis. Also look out for whether the components of the oil piping system are original and meet the manufacturer’s specifications. This is particularly important when taking over a secondhand ship either under management or ownership.

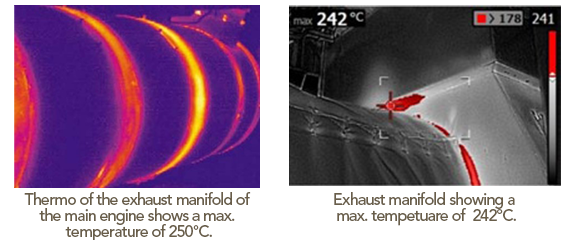

2. Mapping hot surfaces using thermography

Owners/managers should incorporate the use of thermography onboard for detection of hot surfaces and for checking insulation during normal operations. Owners should consider including thermographic examinations in new building specifications and have such tests carried out during sea trials. A thermographic examination of the engine room and the vessel's electrical installation should be carried out periodically with engines and electrical equipment running. It is important to note that spot thermometers have limited effectiveness, as they only measure the temperature at a single point.

The UK Marine Accident Investigation Branch (MAIB) has recommended that the UK Maritime & Coastguard Agency (MCA) submit a proposal to the International Maritime Organization (IMO) requiring the use of thermographic equipment to identify exposed high-temperature surfaces. Additionally, classification societies offer voluntary notations for fire protection in machinery spaces that require the use of thermal cameras for hotspot detection. This raises the question within the industry of whether current statutory regulations and Class rules adequately address the regular identification of machinery space hotspots.

3. Shielding hotspots

Insulation: As materials used to insulate high temperature surfaces may degrade over time or become oil-soaked, regular checks should be carried out. Even if the insulation of an exhaust pipe / system appears to be in good order, there may be hidden inadequately insulated areas and smaller open hot spots which could start a fire if in contact with oil.

Spray shields: The position and condition of spray shields for both high- and low-pressure flammable oil lines should be checked regularly, as should the drainage arrangements for jacketed fuel oil pipes. Where spray shields are not included in the original design and the area has been identified as a potential ‘source of oil leakage’, then the installation of spray shields should be considered. Particular attention should also be given to the immediate and proper refitting of spray shields and insulation materials upon completion of maintenance.

Referring to our initial case study above, making sure that the piping met the original specs, reinstalling the spray shield after maintenance, and using thermography to identify the exposed sections in the insulation around the turbocharger and exhaust manifold of the auxiliary engine would have prevented the fire from occurring.

The engagement of external assistance to conduct these reviews may, from time to time, be considered to provide an independent assessment of potential fire safety hazards within the engine room.

Additional information

Gard

Case study: Engine room fire and failure of fixed fire-fighting systems

Case study: Engine room fire

Case study: Use of fixed carbon dioxide fire extinguishing systems

Poster (high resolution and low resolution) and an alert on “Fires spread faster than you think”

Presentation on shipboard fires: Fire feeds on negligent deeds

Class Societies, IMO and others