Your hands are among the most vulnerable parts of the body as you use your fingers in just about every task undertaken. To ensure protection and avoid injury wear gloves that match not only the hazards of the task but also the size of hand.

Protect your hands and fingers against injury

Published 17 February 2020

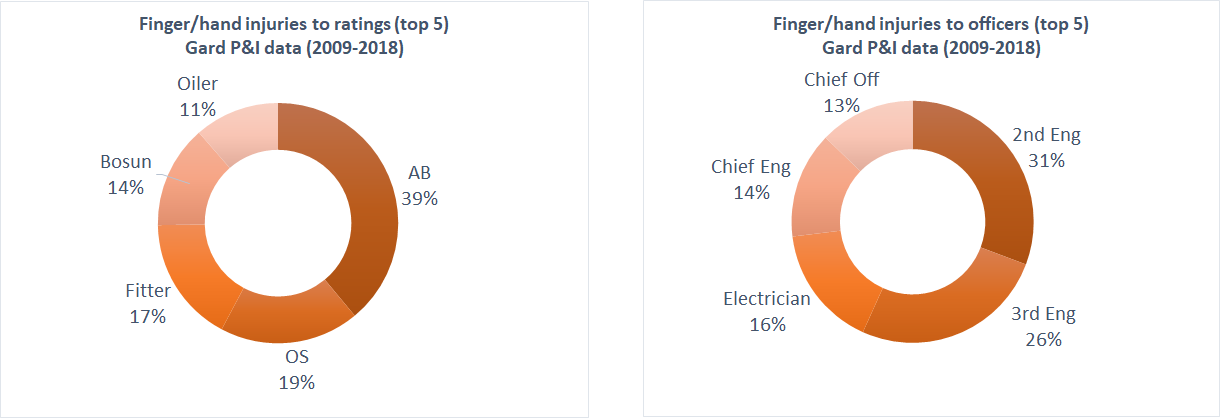

Data from our P&I portfolio for the years 2009 – 2018 shows that over this ten year period some 25% of all crew injury claims are finger/hand injury related. The data also shows that ratings are nearly twice as likely to suffer from such injuries compared to officers. Amongst ratings, the majority of finger/hand injuries happen to able bodied seamen (AB). For officers, marine engineers (second engineer, third engineer and electrician) are most vulnerable. In terms of costs, 15% of all the crew injury claims can be attributed to finger or hand injuries.

There can be many reasons for finger injuries. The level of awareness and alertness of the crew when carrying out jobs requiring physical dexterity are important factors. Awareness comes with experience, knowledge and proper supervision by those who may have carried out such tasks in the past. Alertness, on the other hand, can vary with the time of the day or physical and mental fatigue of the individual involved in the task.

Another common cause is that the crew may have limited understanding as to why hand protection is needed or how to choose an appropriate glove for a particular task. The crew member may end up not wearing gloves at all, or wearing gloves which may not be appropriate for the particular task, or the glove may not fit the wearer. Safety Management System (SMS) should specify not only the tasks that require gloves, but should also mention the type of glove to be used. This is typically achieved through a PPE matrix.

Choosing the right glove

When choosing a glove, the first step is to identify the hazard of the particular task, such as abrasion, cuts, puncture, exposure to chemicals or high temperatures. Size and comfort must also be considered as the glove has to fit the wearer. They can neither be too tight nor too lose. Type and duration of contact with the hazard should also be given due consideration. When selecting the gloves, the Code of Safe Working Practices (COSWP) has some recommendations, such as:

Leather gloves when handling objects which may be sharp or rough

Heat resistant gloves when handling hot objects

Rubber, PVC or synthetic gloves when handling acids, oils, solvents or chemicals

Insulated gloves when working on electrical equipment

Wearing gloves over longer periods

The International Labour Organisation (ILO) adds a cautionary note to the effect that wearing gloves for longer periods can make the skin hot and sweaty and lead to skin problems. The ILO notes that using separate cotton inner gloves can help prevent this.

Remember, that the comfort of gloves, or any PPE for that matter, can have an impact on how the crew member carries out a particular task.