Correct operation and maintenance of equipment, combined with tried-and-tested emergency procedures and crew training, are essential to prevent blackouts on ships and to mitigate their potential consequences.

The importance of blackout awareness and prevention

Published 17 June 2025

Increasing ship complexity raises concerns

Modern ships are becoming increasingly complex due to advancements in technology, regulatory requirements, and the need for enhanced safety and efficiency. As a result, many crew members can find it challenging to completely comprehend the functionality and configuration of a ship's power management system, as well as the potential problems, how to troubleshoot and recover from them.

Gard and other Nordic marine insurers, represented by Cefor, are concerned about the maritime industry’s attention to and capability to effectively manage the risk of blackouts. Even if most blackout incidents do not result in serious accidents, many of them have created dangerous situations that could have easily turned fatal. In March 2025, the Cefor Technical Forum, therefore, issued a memo highlighting the importance of ship operators and crew being aware of and capable of effectively managing the risk of blackouts. The memo in its entirety is available on the Cefor website.

What does a "blackout" mean?

A blackout occurs when a ship suffers loss of electrical power from its main switchboard, typically due to an electrical or mechanical failure in the ship's power generation, distribution, or propulsion systems.

All blackout situations are serious and potentially dangerous. In a best-case scenario, a standby generator will be brought online to restore the main source of electrical power within seconds. However, a sustained blackout with loss of propulsion and steering control can eventually lead to collision or grounding with loss of life, damage to the environment and even total loss of the vessel. The risk of a serious casualty increases when a ship is operating close to shore, near other ships or infrastructure like offshore wind turbines and particularly under adverse weather conditions. The increasing complexity of the integration of operating systems on modern ships has also been shown to challenge crews’ capacity to understand how these systems work. This can have a significant impact on how long it takes to recover from a blackout and restore propulsion and steering, and hence the severity of a blackout.

Regulatory framework

The regulatory requirements for ship construction and equipment, such as electrical power, machinery, and control systems are outlined in SOLAS Chapter II-1, and the performance requirements for main and emergency electrical power sources are primarily addressed in regulations 40 to 44. Another, more comprehensive layer of requirements is also added by a vessel’s classification society, e.g. as per IACS Unified Requirements Concerning Electrical and Electronic Installations, UR E. Furthermore, each classification society may have supplementary requirements for blackout prevention and recovery as part of their voluntary class notations.

However, despite the IMO’s and classification societies’ strong emphasis on system reliability and failure response through design, construction, and inspection standards, a blackout can be caused by a variety of technical or operational failures that may not conflict with the rules and regulations.

The ISM Code then becomes relevant. In terms of safe operation and hazard control, Chapter 10.3 of the Code requires ship operators to: ”identify equipment and technical systems the sudden operational failure of which may result in hazardous situations. The safety management system should provide for specific measures aimed at promoting the reliability of such equipment or systems. These measures should include the regular testing of stand-by arrangements and equipment or technical systems that are not in continuous use.”

Responding to blackout incidents

Past incidents highlight the importance of blackout awareness. For instance, in March 2019, a cruise vessel experienced a blackout during a storm off the Norwegian coast, leading to a loss of propulsion and steering. The accident was caused by insufficient lubricating oil in all of the operating diesel generators’ lubricating oil sump tanks in combination with pitching and rolling in rough seas. With more than 1,300 people onboard, the vessel was less than a ship’s length from running aground before power and propulsion were restored.

The available investigation report indicates that the vessel’s crew encountered substantial challenges when attempting to restore electrical power and propulsion after the blackouts. Reportedly, it took 39 minutes from the blackout until both propulsion motors were operational.

Are blackouts incidents on ships increasing?

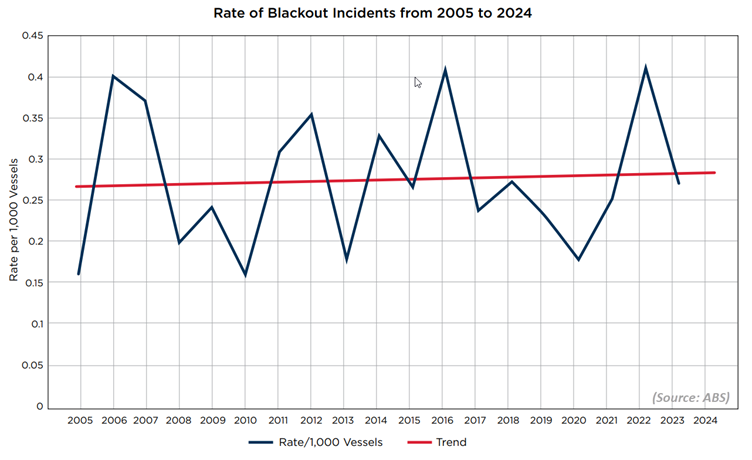

Realistic accident statistics for blackouts on ships are difficult to obtain because most blackouts are probably not reported as “accidents”. However, there seem to be some indications of an increase in event frequency. The figure below is created by the classification society American Bureau of Shipping (ABS) and shows a rising trend in the rate of reported blackouts in the world maritime fleet between 2005 and 2024. Similarly, research by Det Norske Veritas (DNV)found that in 2019, the media reported 12 power loss events on cruise ships that resulted in full or partial blackout while in transit or manoeuvring, a significant increase from four events in the previous year.

Key recommendations

To prevent blackouts from occurring, ship operators must ensure that all essential machinery, electrical equipment and control systems are correctly maintained and operated. According to DNV, some of the typical failures to be aware of are:

Loss of lube oil pressure

Fuel-oil related issues, e.g. clogged filters

Control, monitoring and safety system malfunctions

Common maintenance failures. This could happen when similar maintenance is carried out on several auxiliary engines at the same time

We also recommend carrying out regular and realistic performance testing of auxiliary and emergency power supply systems as well as surveying switchboards with an infrared camera. Even systems with redundant power supply might fail at the worst possible time if not properly maintained.

To reduce the effects of a blackout, ship operators should develop robust operating procedures that identify ship-specific operations where a blackout could represent a particularly high risk, e.g. during berthing or navigation in heavy weather,

different system failures that could occur, and how to best respond if a failure occurs. Special attention should be made to the configuration of main and auxiliary switchboards to provide redundancy in power supply for propulsion and supporting systems.

Additionally, we emphasise to ship operators the importance of having an alarm system that is clear and unambiguous. Every blackout will activate a large number of alarms, and it is essential that the engineers on watch can quickly recognise those that are critical. As an example, the investigation (report in Norwegian) of the above mentioned cruise ship accident revealed that the ship’s alarm system in the engine control room failed to distinguish between critical and less critical alarms, and that “troubleshooting was challenging when a total of approximately 1,000 alarms sounded within the first 10 seconds after the blackout”.

Onboard drills to test system responses triggered by different, and realistic, blackout failures should be conducted on a regular basis to improve crew awareness. The Failure Modes and Effect Analysis (FMEA) of the complete power management system would be a good resource for operations and training of crew. When used as a reference document, it can improve operator understanding of the risks and corrective actions the automation system performs should a particular failure occur. Remember, your best strategy to avoid accidents is to make sure every ship has a skilled and confident crew, who understand how to prevent and respond to a blackout in order to recover as quickly as possible.

Further reading

Further information on procedures to prevent and support quick recovery from blackout situations can be found in the following publications:

The authors thank Mark Russell and Svend Leo Larsen for their contribution to this article.